Pharmaceutical Automatic Blister Cartoning Machine Horizontal & Intermittent DZH-120

DZH-120 Horizontal Automatic Blister Cartoning Machine is suitable for pharmaceutical into carton, such as capsule /tablets blister, liquid in bottle(glass/flat), vial, tube/ointment , plaster, soft strips, injection, tray, syringe, ampoule and condom and sachet/pouch and other products.

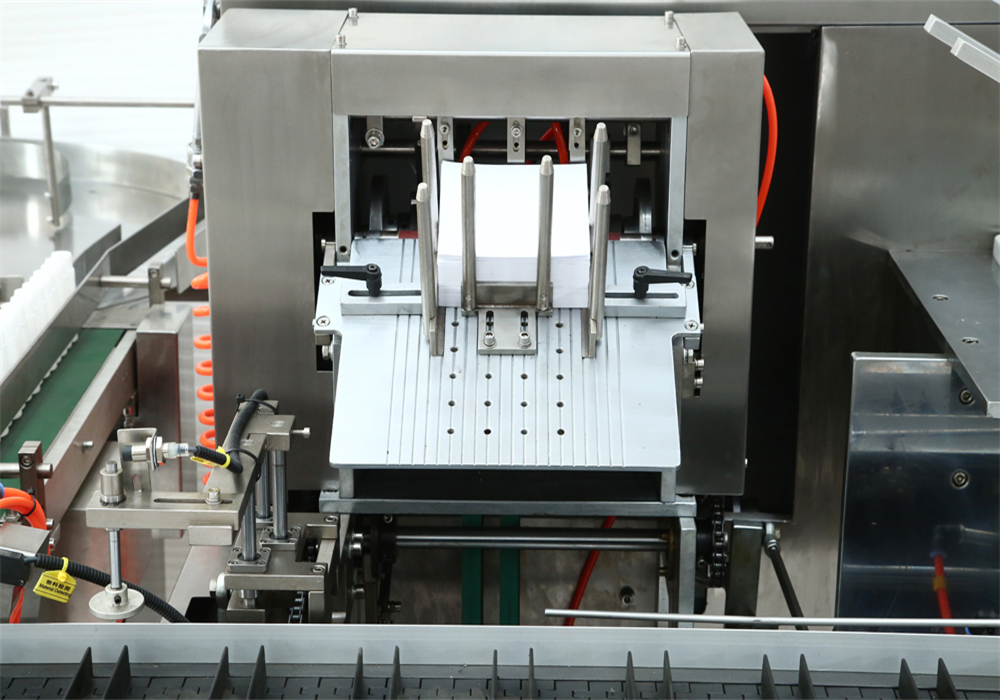

Cartoner with automatic infeed is designed to, automatically open, load and close cartons. you can set the quantity of blister in touch screen, it will be feeding automatically, and folding (1-4 folds) leaflet,cardboard case forming and feeding,batch number printing,sealing carton with tuck-in or hot melt glue device. Automatically leaflet/product detect and reject lacking of leaflet or product .The whole encasing process is finished automatically.

It can connect with blister packing machine and cellophane overwrapping machine to form a Production Packaging Line.

- International famous brand of electric components such for PLC touch screen, frequency inverters,etc.

- Adopt human-machine operation system.

- Automatically displaying device for trouble,speed and finished products counting.

- Machine running without pressing if no products or incorrect position of products. And stopping automatically if incorrect position of product into carton after return or no cartons or out of leaflets continuous.

- No products not suction leaflet, no leaflet not suction carton.

- Automatica detection and rejection device for lacking of blisters goods or leaflets.

- Stable performance,operation is easy.

|

PROJECT |

PARAMETER |

|

|

Model |

DZH-120B |

|

|

Encasing speed |

30-120 case/min |

|

|

Box |

Quality requirement |

250-350g/m*m |

|

Dimension range (L* W* H) |

(50-180)mm* (30-85)mm* (15-50)mm |

|

|

Leaflet |

Quality requirement |

50-65g/m² |

|

Unfolded leaflet specification( L* W) |

(80-300)mm*(70-210)mm |

|

|

Folded leaflet specification(1-4)*(L* W) |

(70-210)mm*(20-40)mm |

|

|

Compressed air |

Working pressure |

0.5-0.7mpa |

|

Air consumption |

300L / min |

|

|

Power supply |

220V 50HZ |

|

|

Motor power |

1.5kw |

|

|

Machine dimension(L* W* H) |

3200mm* 1200mm* 1900mm |

|

|

Machine Weight |

1500kg |

|