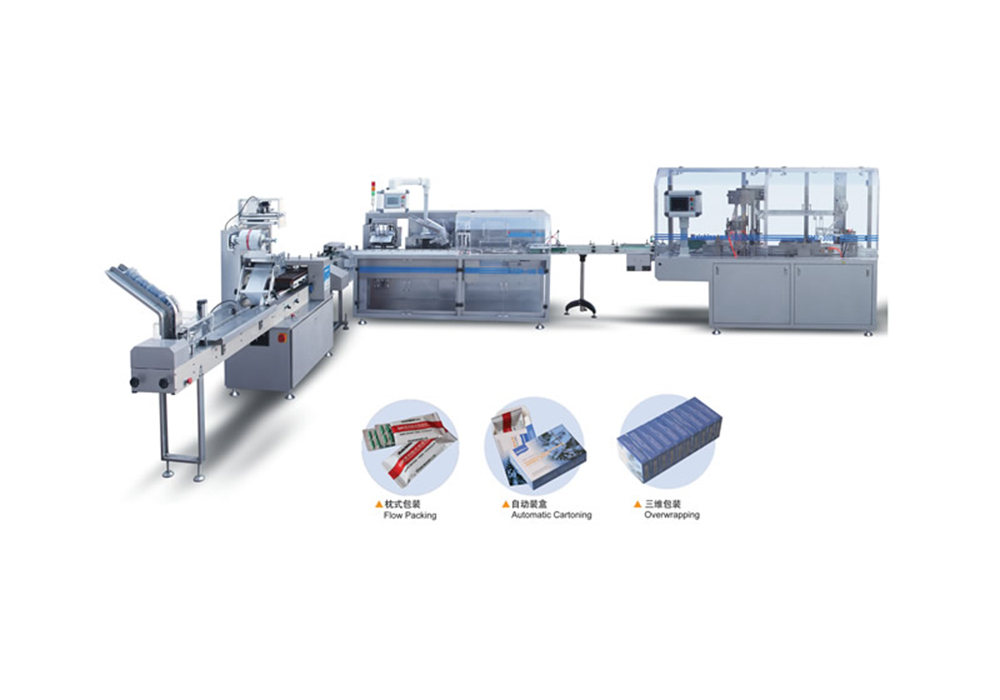

Pharmaceutical Automatic Packaging Line

Main Features Of Flow Pack Machine:

1. Provides protection from light, moisture and dust.

2. Suitable for packing a variety of solid shapes and material.

4. Package cut-off length can be calibrated by hand wheel.

6. Suitable for any heat sealable laminated film such as Polyester/Poly, Polyester/Met, Polyester/Poly, Bopp/Foil/Poly, heat sealable BOPP and Pearlised BOPP etc.

Main Technical Parameters:

|

Model: |

DZP-250D(E) |

DZP-400D(E) |

|

Packing capacity |

30-150packs/min |

|

|

Bag size (mm) double cutter |

L(65-190)*W(30-110)*H(2-40)mm |

L(65-190)*W(30-180)*H(2-60)mm |

|

Max. width of film |

250mm |

400mm |

|

Power supply |

AC220V 50Hz, 2.4KW |

AC220V 50Hz, 3KW |

|

Weight |

700kg |

800kg |

|

Overall dimension (L*W*H,mm) |

4050*650*1550mm |

4200*800*1550mm |

A cartoner or cartoning machine, is a packaging machine that forms cartons: erect, close, folded, side seamed and sealed cartons.

DZH-120 cartoning machine is an intermittent motion cartoner,which picks a single piece from stack of folded carton and erects it, fills with a product or bag of products or number of products horizontally through an open end and closes by tucking the end flaps of the carton or applying glue or adhesive. The product might be pushed in the carton either through the mechanical sleeve or by pressurized air. For many applications however, the products are inserted into the carton manually. This type of Cartoning machine is widely used for packaging foodstuffs, confectionery, medicine, cosmetics, sundry goods, etc.

DZH-120 cartoner machine is equipped with a series of sensors and automatic protective devices to assure the machine runs safely and effectively

It can connect with Blister Machine, Pillow Pack Machine,Overwrapping machine etc., to form a Production Packaging Line.

Gear Device:

The gear drives the carton conveyor chain and blister conveyor chain running in intermittent motion.

Carton Conveyor Chain:

The carton conveyor chain is used to transfer opened cartons to every stations, that can automatically complete the actions of inserting of blister cards and leaflets into cartons, embossing, closing of cartons, discharging of cartons.

Leaflet Conveyor Chain:

The leaflet conveyor chain is applied to send folded leaflets to the blister feeding station then the leaflets and the blister cards are inserted into cartons together.

Carton pick-up device:

The carton pick-up with one set of suction cup can suck the cartons from the carton magazine, open the carton, place it on the carton conveyor.

The Leaflet Folding Device:

The leaflet folding device can make the leaflet fold one to four folds according to customer’s demand .

Inserter device:

The inserter device can push the blister cards into the carton in intermittent motion.

Main Technical Parameters:

|

PROJECT |

PARAMETER |

|

|

Encasing speed |

30-120 case/min |

|

|

Box |

Quality requirement |

250-350g/m*m |

|

Dimension range (L* W* H) |

(50-180)mm* (30-85)mm* (15-50)mm |

|

|

Leaflet |

Quality requirement |

50-65g/m² |

|

Unfolded leaflet specification( L* W) |

(80-300)mm*(70-210)mm |

|

|

Folded leaflet specification(1-4)*(L* W) |

(70-210)mm*(20-40)mm |

|

|

Compressed air |

Working pressure |

0.5-0.7mpa |

|

Air consumption |

120-160L / min |

|

|

Power supply |

220V 50HZ |

|

|

Motor power |

1.5kw |

|

|

Machine dimension(L* W* H) |

3200mm* 1200mm* 1900mm |

|

|

Machine Weight |

1500kg |

|

Overwrapping machine or cellophane overwrapping machine. Overwrapping machine is suitable for the automatic packing of box-shape single objects or box-shape single objects or box-shape many objections such as pharmacy, food, health products, tea, cosmetic present stationary, audiovisual products etc. Overwrapping machine can replace the box in the paper and also can reduce the packing cost about 95%. Using the machine to pack can defend takeproof moisture and proof dust , and etc. Overwrapping machine improve the productions level , increase the productions additional value . Overwrapping machine can be linked to with boxing machine to compose packing production line.

1. Adopting the man-machine interface , PLC control, Failures diagnosing software .

2. Adopting the servo motor to feed film. The speed and the length can be adjusted .Using the film smooth and length accurate.

3. Adopting full cylinder drive .Steady running .accurately Synchronizing .conveniently adjusting hard sealing.

4. Compact structure .Easy to operation and Manipulating.complete safety device

Main Technical Parameters Of Overwrapping machine

|

Model |

TMP-300E |

|

Packaging material |

OPP,BOPP , PVC |

|

Production capacity |

5-30package/minute |

|

Bag size |

L(50-300)* W(40-220)* H(10-100)mm |

|

Power supply |

AC380V 50Hz, 6.5Kw |

|

Working pressure |

0.6 Mpa |

|

Air consumption |

400L/min |

|

Weight |

750kg |

|

Outline dimensions(mm) |

2450*900*1750mm |

|

Size of feed table(mm) |

1650*320*930mm |