Call to Action

Fill out the form to contact us, We promise to respond to you quickly.

Materials for 3D Overwraping Machine

Sep 15, 2025

The evolution of three-dimensional packaging has revolutionized product presentation, protection, and sustainability across industries. This progress is intrinsically linked to advanced materials compatible with automated 3D packaging systems, which enable the formation of complex structural designs while ensuring durability and functionality.

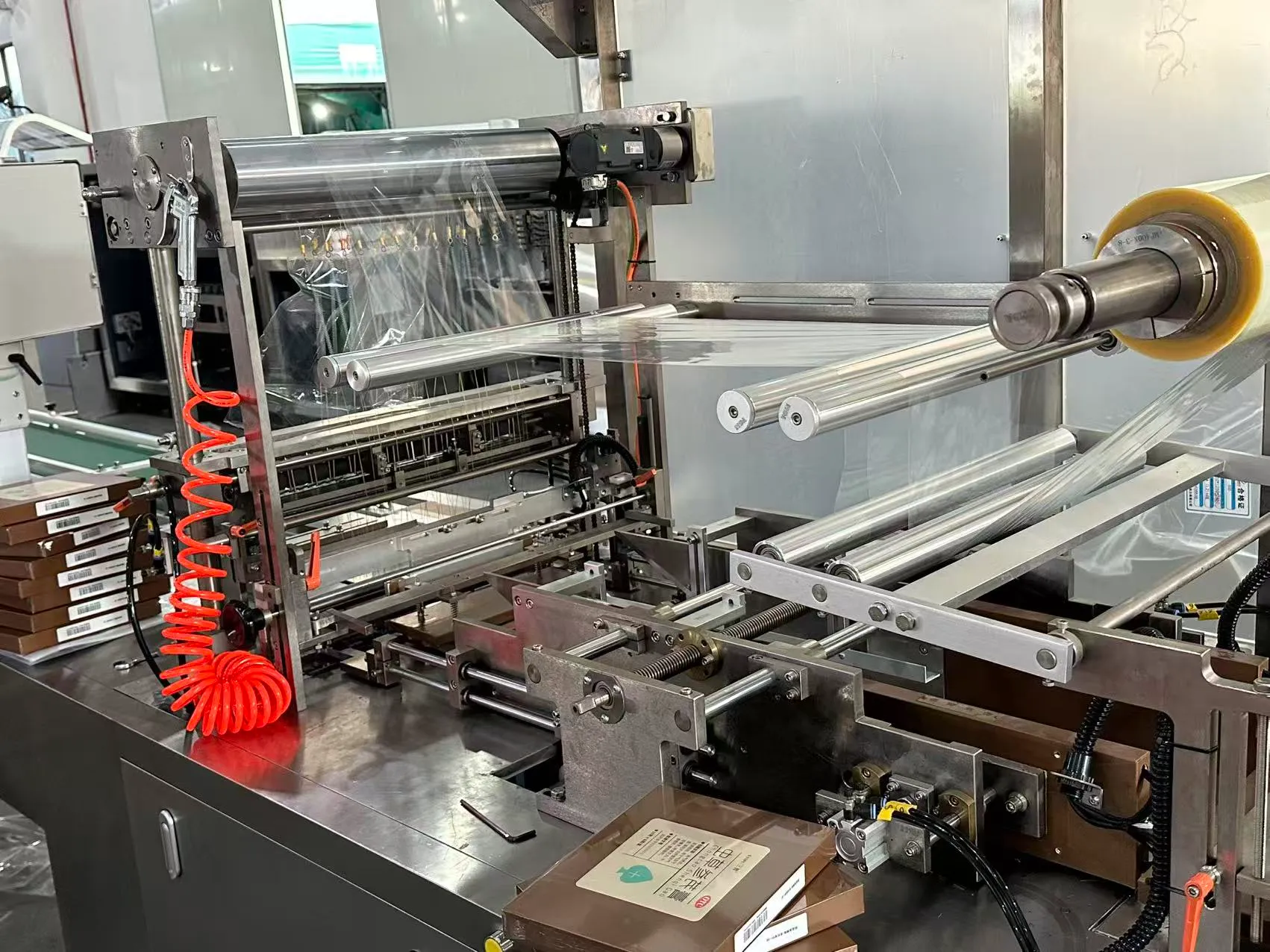

Thermoformable plastics serve as the cornerstone of rigid 3D packaging. Polyethylene Terephthalate (PET) and Polyvinyl Chloride (PVC) are widely used for clamshells, blisters, and custom-shaped containers, offering high clarity, stiffness, and consistent forming behavior during thermal processing. Polypropylene (PP) provides enhanced chemical resistance and is often selected for food and medical packaging due to its safety profile and versatility. These materials enable high-speed thermoforming on automated lines where heating, vacuum forming, and trimming are seamlessly integrated.

For applications requiring barrier properties, multi-layer laminates and ethylene-vinyl alcohol (EVOH) coatings are employed to protect sensitive products from oxygen, moisture, and light. These materials are essential in food packaging, pharmaceuticals, and electronics—often combined with sealing layers such as polyethylene (PE) to ensure package integrity.

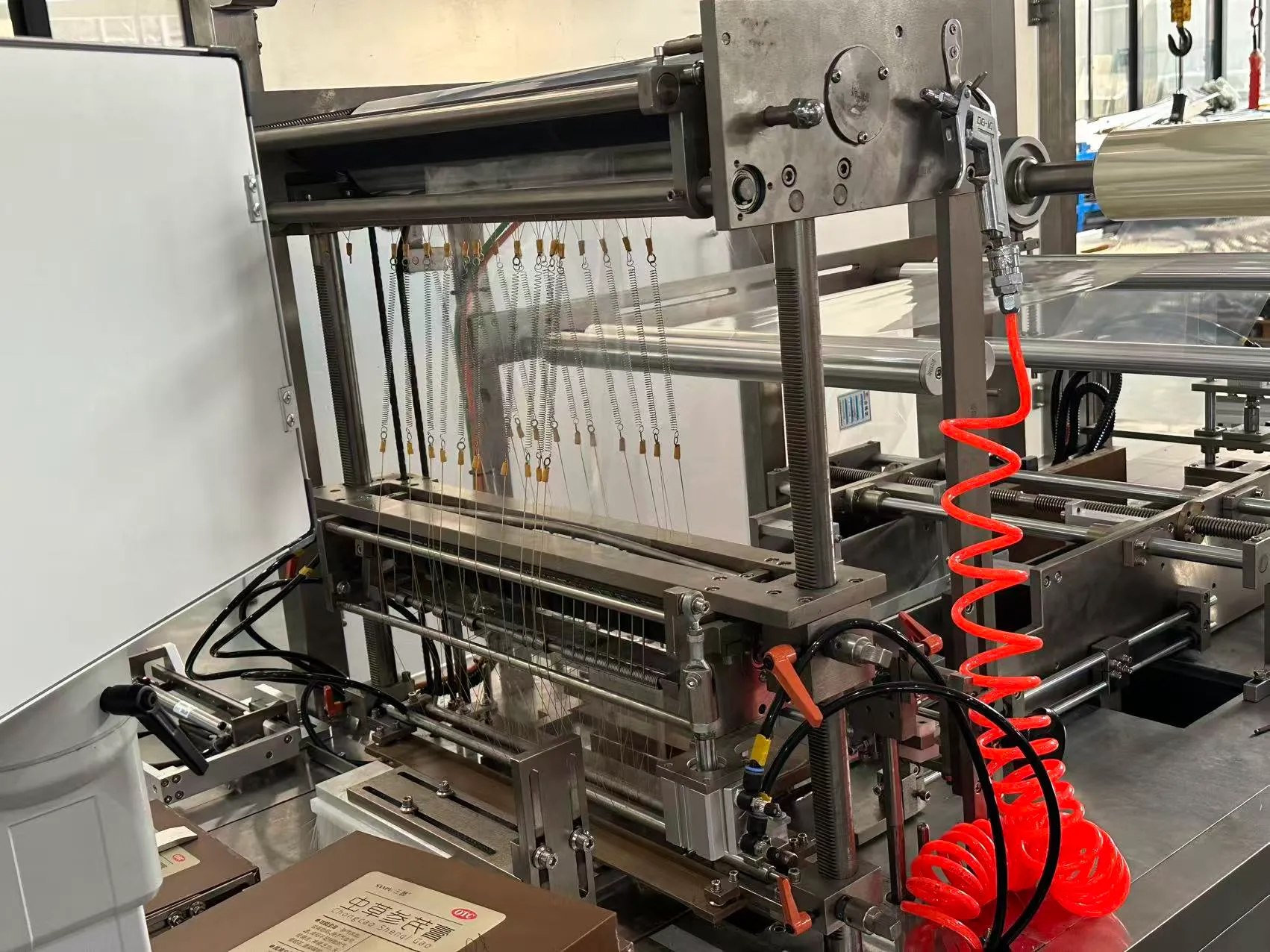

Sustainable alternatives are increasingly shaping the material landscape. Polylactic acid (PLA) and other compostable biopolymers are gaining traction for eco-conscious retail packaging. Similarly, molded fiber and paperboard offer renewable and recyclable options for protective 3D packaging. Modern machinery has adapted to handle these materials through adjustable dwell times, temperature zones, and specialized sealing jaws.

Advanced composites and shape-memory polymers represent the next frontier, allowing packages to be reshaped or reused. Such innovations require packaging machines with highly precise thermal control and adaptive actuation systems.

Material selection directly impacts machine performance. For instance, forming depth, sealing consistency, and production speed are all influenced by material thickness, melt index, and surface energy. As new materials emerge, packaging machinery must incorporate enhanced sensing, real-time adjustment capabilities, and compatibility with circular economy objectives.

In summary, the synergy between innovative materials and advanced machinery continues to expand the possibilities of 3D packaging—enabling brands to merge aesthetics, functionality, and sustainability in increasingly sophisticated ways.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Sep 26, 2025

The Export Strategy for Cartoning Machines

Sep 05, 2025

Adapting to the Needs of Diverse Industries

Sep 01, 2025

The Operating Principles of Packaging Machinery